The original and best measuring stop system

Save time, money and materials

It is cost effective to install, simple to use and saves the time and effort of measuring, marking and clamping blocks of wood to a machine fence.

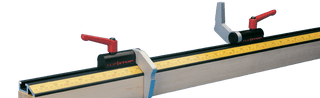

FLIPSTOP consists of a metal track with measuring scale which is fitted to a fence. Pivoting stops are moved along the track to the required position. When not in use the stop is simply flipped up and out of the way.

A number of stops can be fitted onto the track which makes it possible to keep multiple settings on a single unit

and simply to ‘flip’ between settings with no further adjustments. In this way, FLIPSTOP can reduce set up time by as much as 80% and often reduce handling by 50%. This time saving can result in substantial cost reductions.

Whether machining one piece to size or working through a lengthy cutting list, FLIPSTOP will speed production by removing the measuring and marking process.

FLIPSTOP is compatible with most types and makes of manual machine tools used for wood, metal and plastics, including radial arm or sliding table saws, chop saws, spindle moulders, pillar drills, routers or guillotines.

Highly versatile, FLIPSTOP is simply screwed to a 45mm high fence (standard ex 2” stock) mounted on the machine. The FLIPSTOP track is available in 1m, 2m and 3m lengths. The track can be fitted with left or right reading measuring scales to allow fitting on either side of a machine. The stops are also reversible. This allows adjacent stops to be set close together as well as permitting left or right handed use.

FLIPSTOP gives accurate, repeatable measurements and can be fitted to most manual machine tools to improve productivity and save money

The position of the track can be adjusted 5mm left or right for accurate calibration

Yellow measuring scale, recessed into black track for protection, is highly visible. The stop arm is shaped to fit into the recess to allow fast accurate placement of the stop.